How a Handmade Tie Is Made: Behind the Scenes

Behind every handmade tie lies a story of skilled hands, precise steps, and carefully chosen materials. In this article, we take you inside the Filippo Marchesi workshop to discover — step by step — how a luxury tie comes to life.

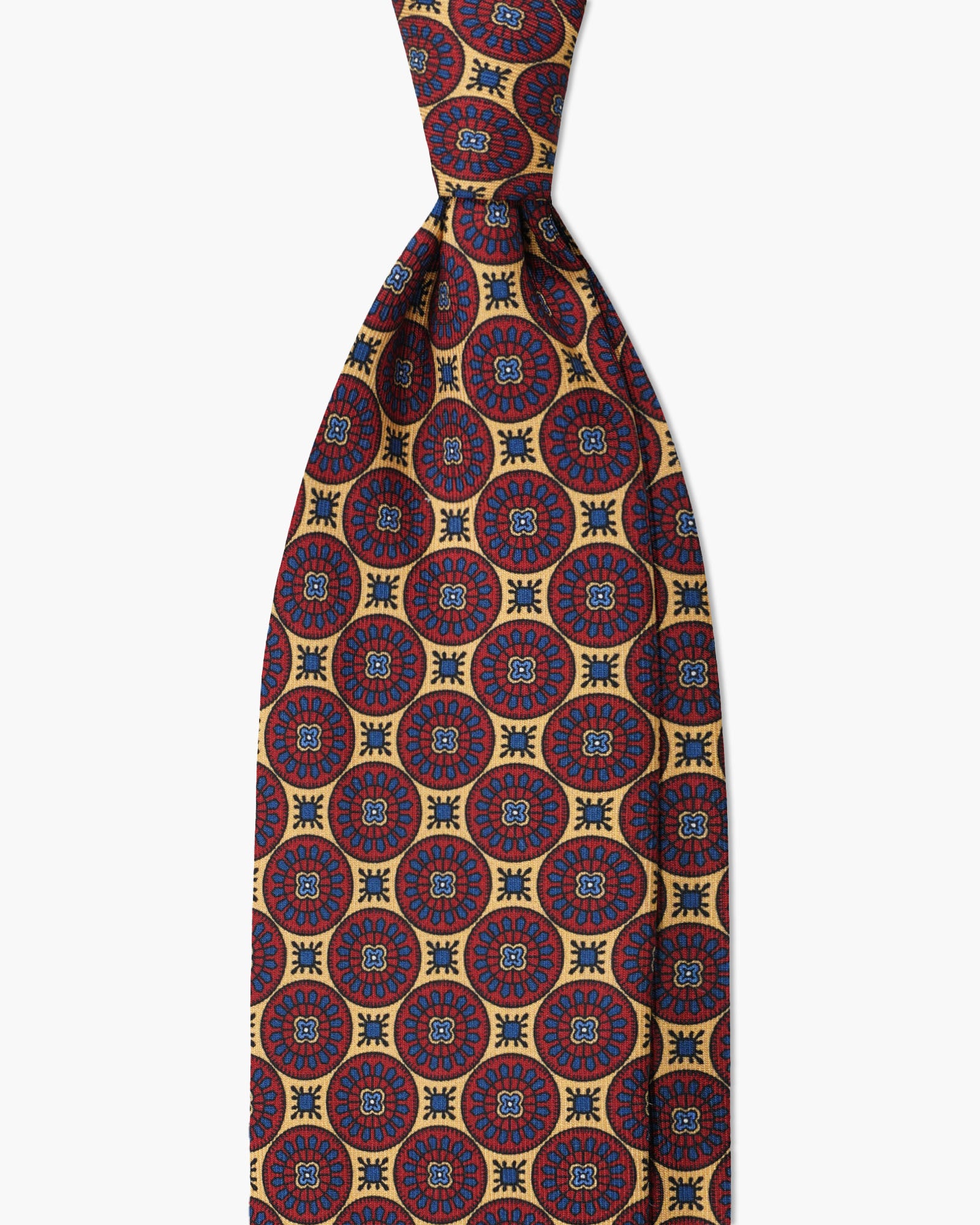

Selecting the Fabric

It all starts with the fabric. Italian silk, grenadine, wool, or linen — each material is chosen not only for its beauty but for how well it folds, knots, and drapes.

Cutting the Fabric

The fabric is hand-cut on the bias — a diagonal direction that provides elasticity and structure to the knot. Every component — blade, tail, and interlining — is cut with millimetric precision.

Hand Assembly

Each piece is then sewn together by hand using invisible stitches. This is where the tie’s true structure is formed — its final width, symmetry, and ideal tension to avoid unwanted creases.

Folding Technique (3, 5, or 7 Folds)

The fold is the artisan's signature. A 3-fold, 5-fold, or 7-fold tie requires different techniques and time. More folds mean more fabric and a richer, more structured appearance — a symbol of craftsmanship.

Final Touches and Quality Control

Label, keeper loop, and interlining are applied one by one. Each tie is steamed, visually inspected, and folded with care before packaging.

The Soul of Italian Craft

Every Filippo Marchesi tie represents patience, precision, and passion. A product made to last, tell a story, and represent the man who wears it.

Conclusion

Creating a handmade tie means uniting technique, art, and tradition. And knowing how it’s made allows you to appreciate its value even more.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.